for IFSYS feeding technology

Our IFSYS offer is rounded off with suitable components and ideal Accessories: We offer upstream technology such as disentangling systems or bunker belts as well as downstream provisioning solutions of any kind.

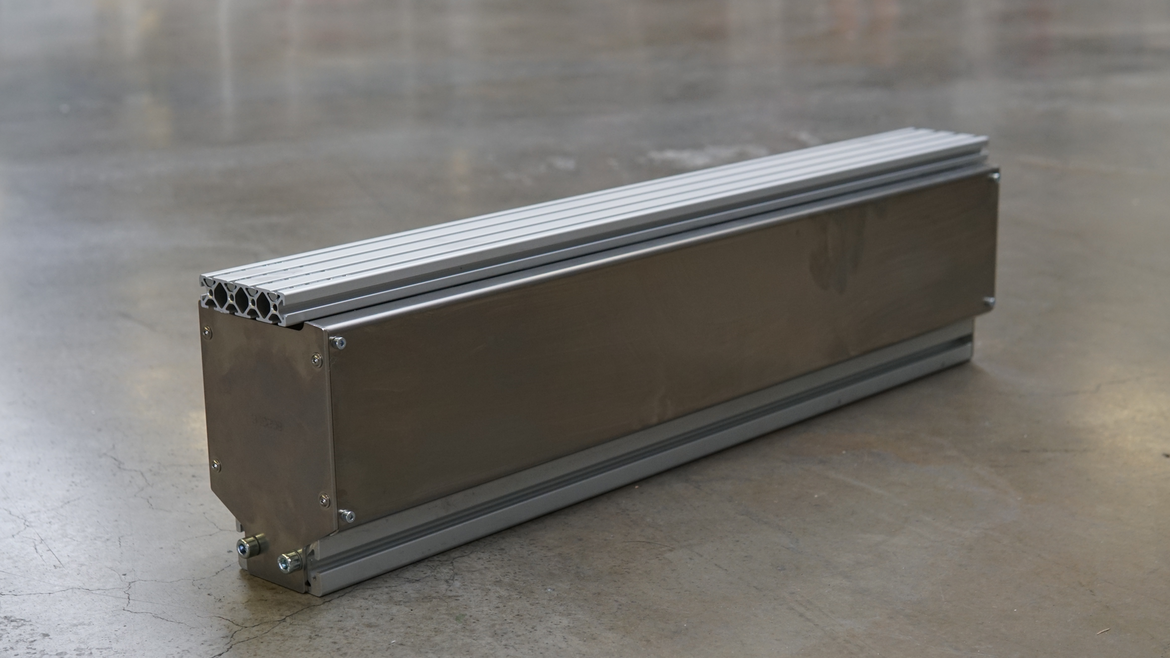

The Vibroliner® has been at the heart of the innovative strength of IFSYS since it was founded. Thanks to the good scalability and the diverse integration options, the Vibroliner® technology in combination with other feed systems forms the basis for optimum quality and reliability.

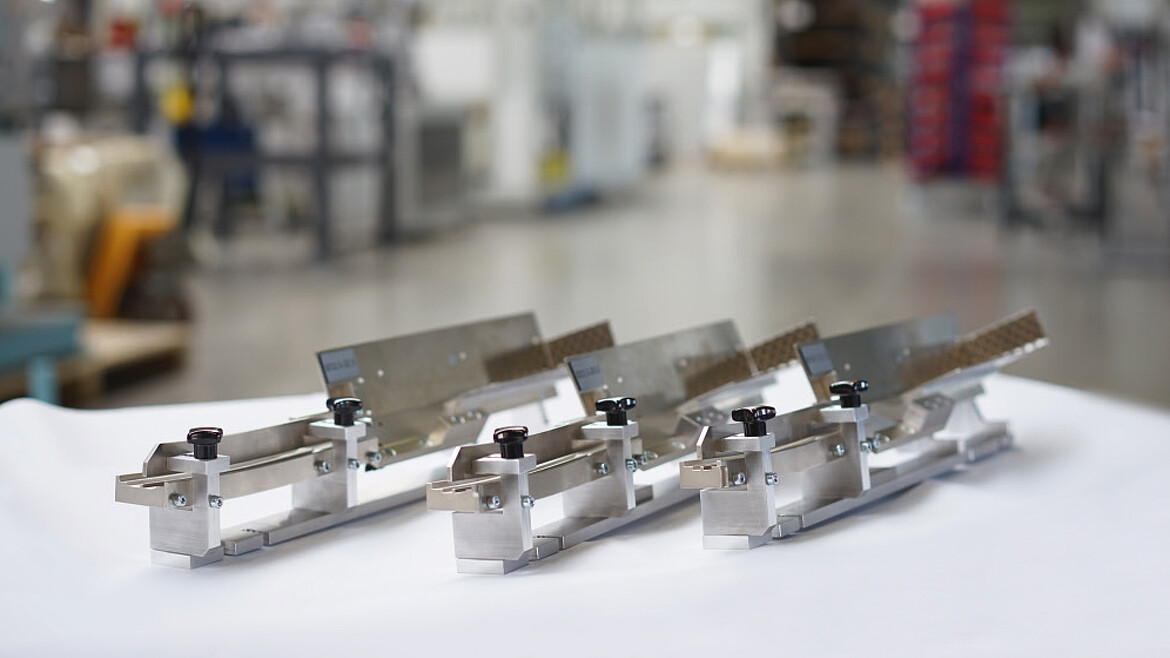

The advantages of the IFSYS systems compared to other systems quickly become apparent. High feeding capacities with low noise emission are just as feasible as flexible applicability due to compact dimensions and exchangeable components. In addition, maximum part protection is achieved and the susceptibility to failure is reduced.

The step feeder is one of the most used feeding systems and is mainly used for pre-sorting and metered feeding of IFSYS vibroliners.

IFSYS step feeder, just like our other feeding systems, are characterized by their well thought-out design, optimum feeding performance and high reliability. Gentle handling of the conveyed parts and the lowest possible noise level are just as much a focus as meeting special requirements.

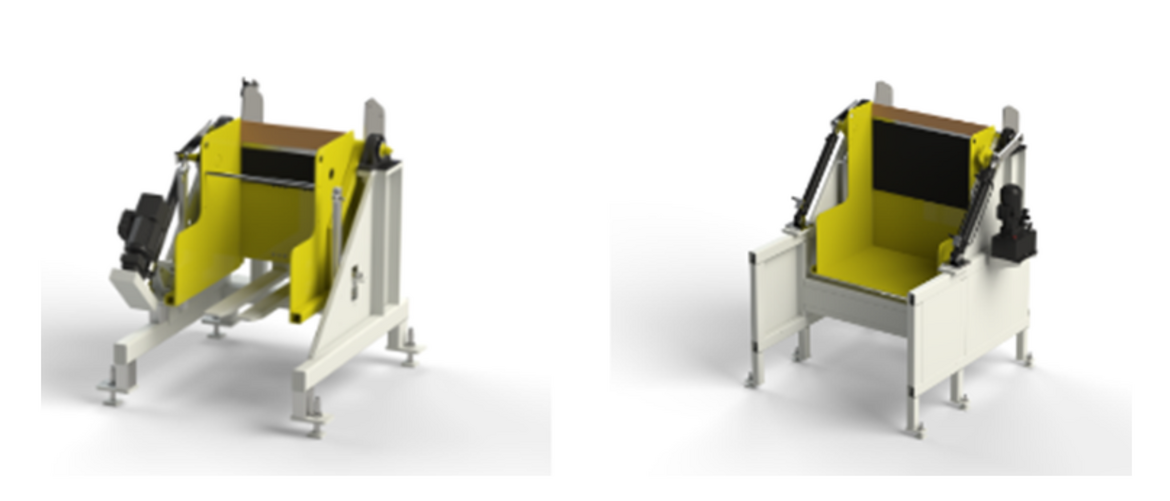

Our tilting devices are the ideal solution for automating manual processes in production, making the working environment more ergonomic and increasing efficiency. We design each tilting device individually according to customer requirements so that it fits perfectly with the specific containers and production processes. Thanks to our expertise, everything comes from a single source – from planning to commissioning.

Our tilting devices offer a number of advantages that have a direct impact on production processes:

We offer two types of tilting devices, which differ in terms of their drive type and load capacity:

Safety is our top priority. Our tipping devices can be equipped with the following optional features::

Would you like to know more? For further information on our feeding systems or feeding modules, we kindly refer to the specific product descriptions.

If you are interested, please get in touch with us.