Your quality of products and processes is 100% checked

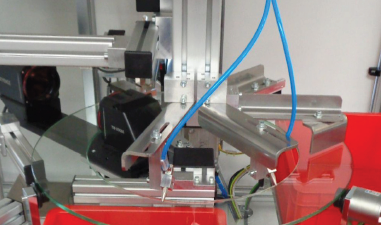

We supply everything from a single source: feeding, measuring with high-performance camera systems and sorting for the further production process.

Feeding is our strength, you can rely on it. With our experience in the field of feeding technology, we provide the sorting parts at any time, in the right quantity and position, within fractions of a second, for the next step in the measuring process.

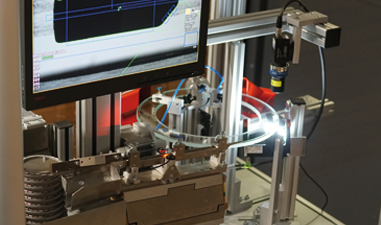

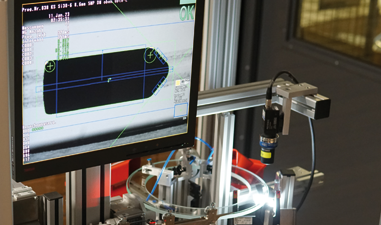

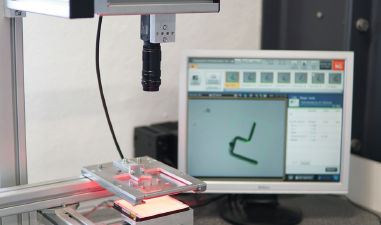

Criteria such as length, diameter or surface are detected and evaluated using industrial image processing. This is done with a speed and accuracy that a human could never achieve with the naked eye.

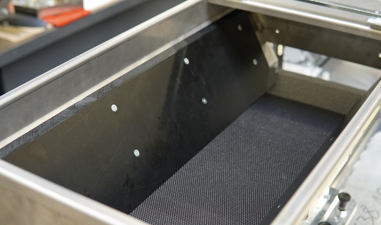

Depending on the test and measurement criteria, the parts are categorized and sorted into the designated containers.t.

In addition to completely new systems, we at IFSYS also offer maintenance and optimization for existing machines. Together with you, we always find the best solution.

FeedingTechnology: Our strength

Automated part feeding combined with tailor-made test and measurement technology enables a safe and efficient production process for your components. As a specialist for feeding technology and the know-how for testing and measuring systems, we cunstruct the perfect overall solution for your individual application. Your advantage: Everything from a single source and tailor-made.

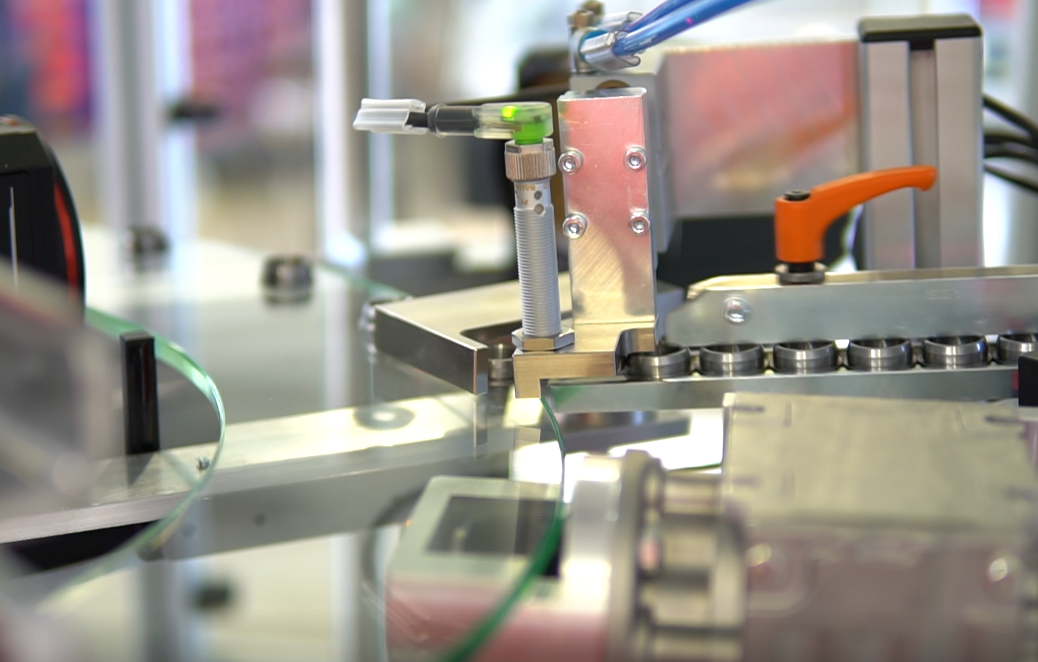

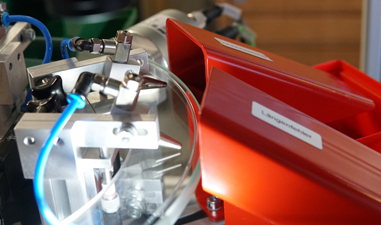

Our integrated inspection and measurement technology ensures that sorted feeding parts are inspected within fractions of a second during the feeding process. Using camera recognition, the individual parts are checked for various criteria such as length, diameter or surface, some of which cannot be seen with the naked eye, and are sorted out directly in the event of damage.

Do length, diameter and surface fit?

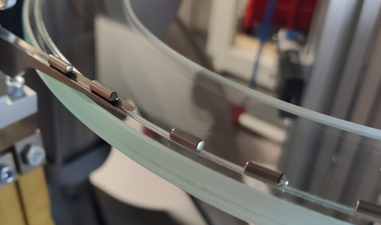

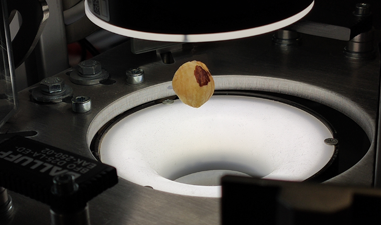

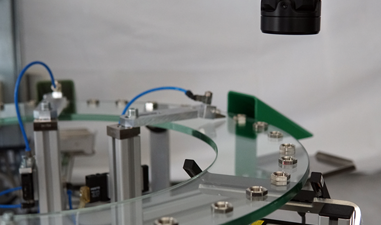

Our measurement technology enables reliable inspection and sorting of measurement and test objects using optoelectronic sensors and cameras that are individually adapted to each specific task. A proven IFSYS feeding system places the measurement and test objects onto a glass ring and then into the detection area of the image processing system. The glass ring offers a particular advantage, as it allows viewing from almost all perspectives. This enables dimensional accuracy, surface quality (e.g., scratches), deformations, and other relevant quality characteristics to be captured with exceptional precision. Sorting is then performed based on the evaluation results.

Solutions for test and measurement technology

Various evaluation options - from parameters to self-learning software

The 100% quality-controlled parts are separated by targeted air blasts. These bring the parts reliably from the glass disc to the following process within fractions of a second. Parts that are not blown off are drifted off the glass disc and can be disposed of or repeatedly fed and inspected.

From the simplest separation of good and wrong parts to complex classification using self-learning software, we have the right solution for your requirements.

.

Sorting solutions

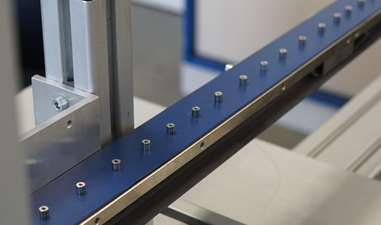

Interfaces to follow-up processes

We have the right solutions for a continuous material flow. Conveyor belts, slides, lift systems and other options are part of the IFSYS modular feeding system.

Do you need your parts to be packed? Then we can count, pack, label and also palletize them. In order to achieve 100% quality control at the end, we determine the right measurement method right from the start and carry out test measurements. We provide you with the resulting feasibility studies free of charge and advise you in detail until the implementation.

.

Interface solutions

Would you like to know more? For further information on our feeding systems or feeding modules, we kindly refer to the specific product descriptions.

If you are interested, please get in touch with us.